Introduction

In industries such as food processing, pharmaceuticals, and chemicals, achieving a uniform blend of ingredients is essential for maintaining product quality and ensuring regulatory compliance. Consistency in blending affects everything from shelf life and texture to efficacy and safety. Advances in mixing technology are enabling the delivery of superior mixing performance, with next-generation industrial mixer systems leading the way in both precision and efficiency.

Manufacturers are increasingly demanding not only operational speed and energy efficiency, but also reliable reproducibility, to meet higher market standards and reduce wastage. The latest innovations in industrial blending are addressing these needs by combining digital intelligence, enhanced mechanical designs, and sustainable solutions into powerful new systems.

Modern mixing techniques consider not only how well materials are combined, but also how quickly and sustainably this can be achieved. Consequently, innovations target areas such as automated parameter tuning, decreasing labor requirements, and enhanced safety measures. Food Engineering Magazine reports that effective blending has become fundamental for scalable and sustainable manufacturing, impacting both profit margins and market expansion.

3D Blade Designs: A Game-Changer in Mixing

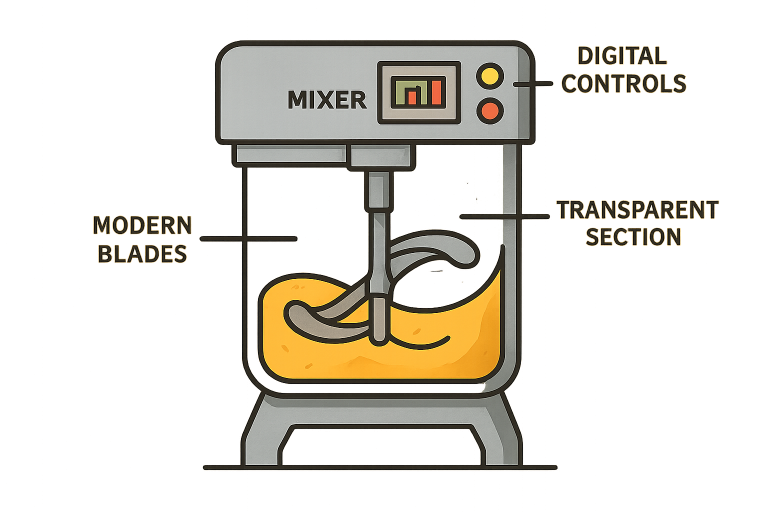

Traditional industrial mixers could struggle to break up stubborn materials, particularly at larger scales. 3D blade innovations have dramatically improved performance by engineering blades that create multidirectional flow within the vessel. This means ingredients are swept both horizontally and vertically, reducing dead spots and ensuring every component is uniformly mixed. These designs have notably shortened mixing cycles and substantially improved batch quality. Companies adopting the latest 3D blades have noted measurable improvements in texture and consistency, especially important in food and pharmaceutical applications.

Smart Mixing Systems: Integrating Automation

Automation is revolutionizing the mixing industry. Smart mixing systems utilize sensors and digital controls to monitor viscosity, temperature, and blend uniformity in real-time. Automated feedback enables these mixers to dynamically adjust speed, blade angles, and mixing times, thereby improving efficiency and ensuring batch-to-batch reproducibility. These systems minimize operator intervention, promote labor safety, and reduce the risk of human error. Highly valued in industries with strict quality benchmarks, smart systems empower both large-scale manufacturers and specialty producers to compete globally.

High-Shear Mixing: Enhancing Homogeneity

High-shear mixing uses exceptionally fast-moving blades or impellers to deliver rapid and intense mechanical agitation. This method is particularly effective at breaking down solids and ensuring that emulsions and dispersions are uniform, minimizing clumping or uneven distribution. High-shear mixers are essential for products that demand tight control over particle sizes, like creams, gels, or specialty chemicals. The resulting finer and even blends can dramatically reduce ingredient usage and the need for post-processing corrections.

Ultrasonic Dispersion: Leveraging Sound Waves

For applications where traditional blade mixing reaches its limits, ultrasonic dispersion offers a compelling alternative. By employing high-frequency sound waves, ultrasonic mixers generate microscopic cavitation bubbles within the mix. These tiny, energetic events cause particles to break apart and distribute evenly throughout the medium. The result is ultra-fine particle sizes and stable emulsions that enhance visual clarity and stability, making this technique popular in high-precision paints, pharmaceuticals, and coatings.

Vacuum Mixing Systems: Achieving Smoother Textures

Mixing under vacuum conditions removes air that would otherwise get trapped in viscous or dense materials. Vacuum mixers excel at producing smooth, lump-free textures, which are essential for products such as sauces, cosmetics, and pharmaceutical creams. By eliminating unwanted air, these mixers also help prolong shelf life and preserve product color and flavor. For ready-to-eat meals, dressings, and dairy-based foods, vacuum mixing technology ensures that every bite meets rigorous sensory standards. Furthermore, reduced oxidation during vacuum blending protects sensitive ingredients from degradation.

ResonantAcoustic® Mixing (RAM): Efficient Energy Use

Resonant Acoustic Mixing, or RAM, utilizes controlled acoustic energy to agitate and blend materials efficiently. This innovation not only dramatically shortens mixing times but also significantly reduces energy consumption, making it a sustainable solution for high-throughput operations. RAM’s unique method reduces equipment wear and simplifies cleaning, making it ideal for frequent product changeovers commonly found in agile manufacturing environments. RAM mixers are gaining popularity in sectors where precision, speed, and energy efficiency are paramount.

Conclusion

With sector demands increasing for quality, speed, and sustainability, today’s industrial mixing technologies are moving quickly beyond the basics. Manufacturers adopting 3D blade designs, automated systems, and advanced methods like high-shear, ultrasonic, and vacuum mixing are reaping significant rewards—consistent results, enhanced safety, and improved efficiency. As digital intelligence and innovative hardware reshape the blending landscape, ongoing investment in new technologies will define market leaders and raise industry standards globally.